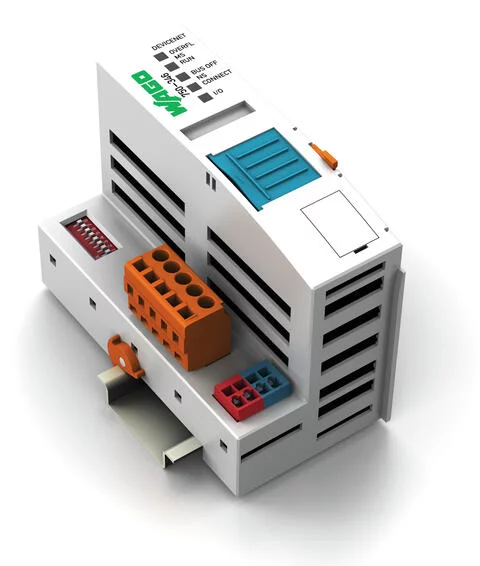

750-346 - Fieldbus Coupler DeviceNet; ECO

- Brand: Wago

- Product Code: 750-346

Notes

Note | Note: Configuration files required (EDS)! |

Technical data

Communication | DeviceNet |

Number of fieldbus nodes on master (max.) | 64 |

Number of I/O points | 6,000 |

Baud rate | 500 kBd (125 kBd, 250 kBd, 500 kBd) |

Bus segment length (max.) | 500 m |

Transmission medium | Shielded Cu cable; Remote bus cable: 2 x 0.82 mm² + 2 x 1.7 mm²; Drop cable: 2 x 0.2 mm² + 2 x 0.32 mm² |

Number of modules per node (max.) | 64 |

Input and output process image (fieldbus) max. | 32 bytes/32 bytes |

Supply voltage (system) | 24 VDC (-15 … +20 %); via pluggable connector |

Current consumption (5 V system supply) | 350 |

Total current (system supply) | 650 |

Input current via DeviceNet interface at 11 V | 120 |

Input current (typ.) at nominal load (24 V) | 260 |

Power supply efficiency (typ.) at nominal load (24 V) | 80 |

Connection data

Connection technology: communication/fieldbus | DeviceNet: 1 x Male connector; 5-pole |

Connection technology: system supply | 4 x CAGE CLAMP® |

Connection technology: device configuration | 1 x Male connector; 4-pole |

Connection type 1 | System supply |

Solid conductor | 0.08 … 1.5 mm² / 28 … 16 AWG |

Fine-stranded conductor | 0.08 … 1.5 mm² / 28 … 16 AWG |

Strip length | 5 … 6 mm / 0.2 … 0.24 inches |

Note (conductor cross-section) | 14 AWG: THHN, THWN |

Physical data

Width | 49.5 mm / 1.949 inches |

Height | 96.8 mm / 3.811 inches |

Depth | 71.9 mm / 2.831 inches |

Depth from upper-edge of DIN-rail | 64.7 mm / 2.547 inches |

Mechanical data

Mounting type | DIN-35 rail |

Material data

Color | light gray |

Housing material | Polycarbonate; polyamide 6.6 |

Fire load | 1.631 |

Weight | 115 |

Conformity marking | CE |

Environmental requirements

Ambient temperature (operation) | 0 … +55 °C |

Surrounding air temperature (storage) | -25 … +85 °C |

Protection type | IP20 |

Pollution degree (5) | 2 per IEC 61131-2 |

Operating altitude | 0 … 2000 m / 0 … 6562 ft |

Mounting position | horizontal (standing/lying); vertical |

Relative humidity (without condensation) | 95 |

Vibration resistance | per IEC 60068-2-6 |

Shock resistance | 15g per IEC 60068-2-27 |

EMC immunity to interference | per EN 61000-6-2 |

EMC emission of interference | per EN 61000-6-4 |

Exposure to pollutants | Per IEC 60068-2-42 and IEC 60068-2-43 |

Permissible pollutant concentration H2S at a relative humidity < 75% | 10 |

Permissible pollutant concentration SO 2 at a relative humidity < 75% | 25 |