V275-P46Z6103P-CC - V275 In-Line Verifier and Print Quality Label Inspection System

- Brand: Omron

- Product Code: V275-P46Z6103P-CC

- Complete inspection solution including Zebra ZT610 or ZT620 printer with factory integrated floating head inspection camera and state of the art inspection software, providing real time complete label inspection.

- Ethernet based communication between the inspection system and the PC or server

- Highly visual, Web UI for configuration, run time label view, data archiving, user management, and audit trail

- Supports continuous label printing, single label tear-off, or peel and present

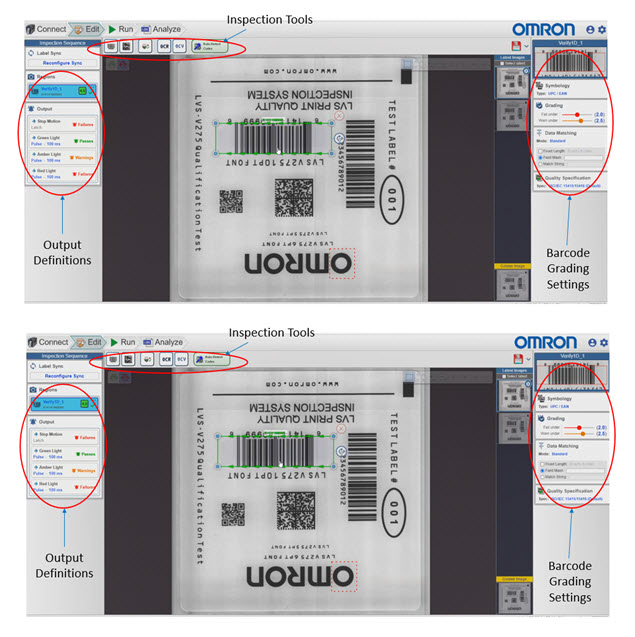

- Advanced label inspection design tools for grading labels to ISO and GS1 standards, including syntax checking, OCR and OCV of alphanumeric characters, and blemish detection of symbols, logos, and other label content

- ISO 15426 Declaration of Conformity, providing assurance that V275 complies to stringent standards required for barcode verification equipment

- API for integration of inspection information into other software applications

- Optional Ethernet based light tower for visual alarms

- Optional IQ/OQ/PQ for use in validated environments requiring CFR 21 Part 11 compliance

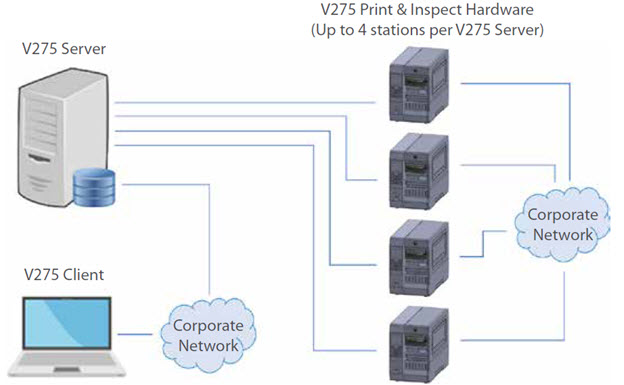

- Ability to network multiple printers into a single PC or Server

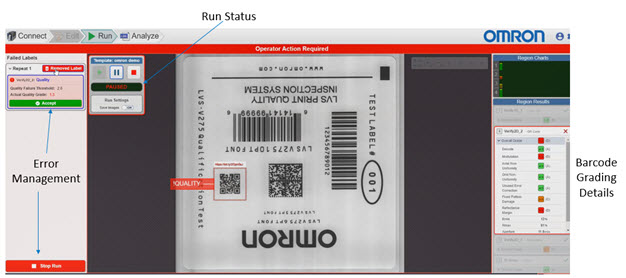

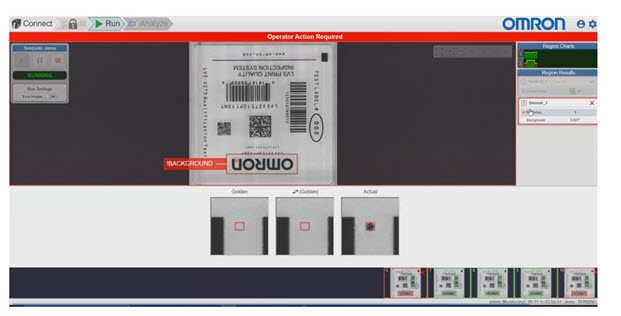

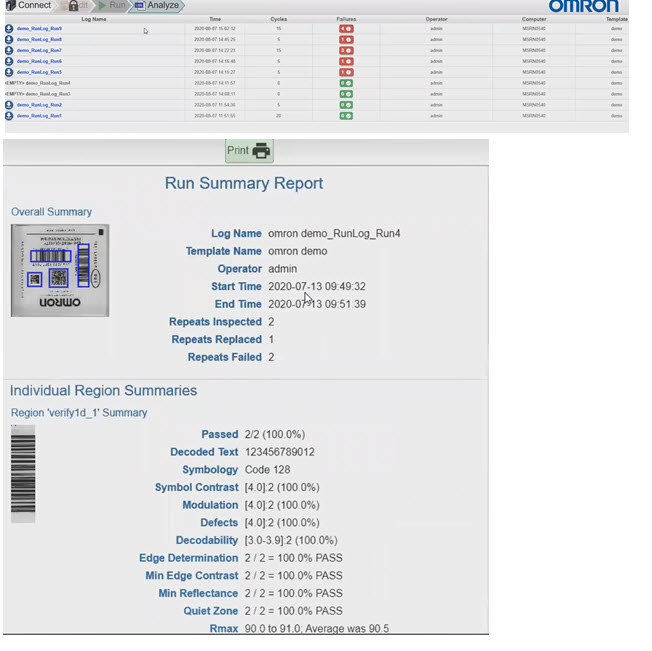

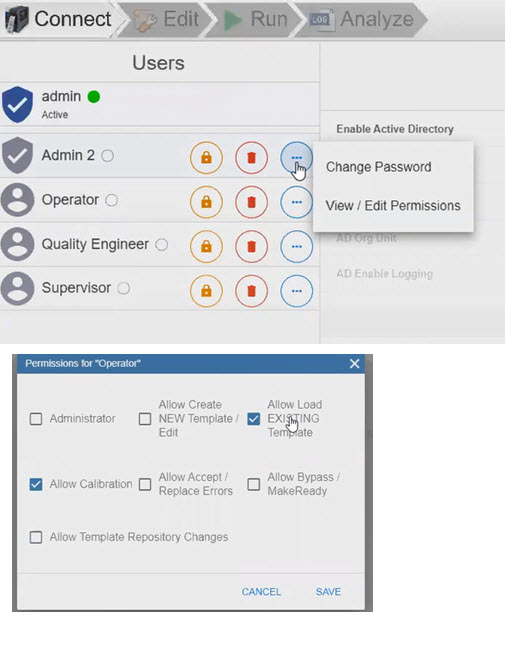

- V275 uses a web based server/client software architecture with the Gigabit Ethernet connection between the PC or server and the V275 printer clients.� The V275 system architecture is designed to allow the flexibility to locate the V275 Server component in a central location, while accessing and controlling the system from any computer with a web browser and authorized access.**Inspection Template Design**The V275 interface provides an ability to customize the label inspection parameters and error thresholds, with the ability to share templates across multiple V275 systems.� Inspection tools for 1D/2D barcode grading, OCR/OCV, data matching for serial # tracking, and blemish detection for logos, symbols or other static label information are available.� Physical outputs that alarm operators via an audible or visual alarm, or other methods are defined via the inspection template.**Run Time Viewing and Error Notification**The V275 run time GUI provides local and remote operators an ability to select an archived inspection template, view real-time inspection results, zoom in on label defects, and a filmstrip view of the inspected labels.Multiple output options for error notification including stop relay interface to the printer, external light stack, and on-screen warning set to user-defined thresholds.**Run Log and Inspection Reports**All print job inspection results are time stamped, and persist on the V275 server for later retrieval and viewing using the client UI.**Audit Trail**The LVS V275 is 21 CFR Part 11 compliant-ready with multiple security levels, comprehensive data management, and reporting options. Microsoft® Active Directory, audit trail of operator actions, and inspection archive for each label. V275 maintains a complete audit trail to allow compliance with internal and regulatory quality mandates. The audit trail can be viewed and exported as a csv or pdf file for archiving in data historians or other applications. The audit trail is accessible only to V275 System users who are authorized to view it.**User Management**By assigning each operator a unique login and the appropriate permissions, the system administrator can create a system that allows some users the right to have full access to the system and to create print inspection templates—while other users can bypass the design and setup functions and move straight to running and inspecting a print job.� If the server uses an Active Directory network, then you can setup� user accounts once on the Active Directory server, and then configure the V275 to connect to that server and let it handle user authentication services.**REST API**For users wanting to interface data from V275 software into other applications a REST API is available.

Specifications

2D Verification x-dim | 10 mil |

Code Type | 2D and 1D Codes |

Mounting | Printer Integrated |

Sensor | 600 dpi line scan camera |

Special function | OCR, OCR, blemish |

Type | In-Line Print Quality Inspection System |

Type | In-Line Print Quality Inspection System |

Special function | OCR, OCR, blemish |

Code Type | 2D and 1D Codes |

2D Verification x-dim | 10 mil |

Field of view | 100mm wide |

Mounting | Printer Integrated |

Sensor | 600 dpi line scan camera |

Printer Operation | Continuous, Tear-off, Peel and Present |