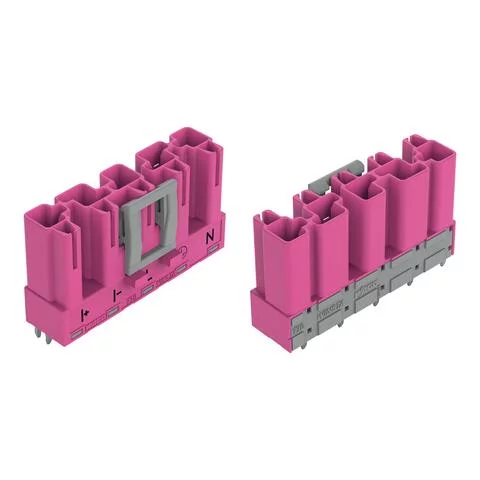

770-895/080-000 - Plug for PCBs; straight; 5-pole; Cod. B; pink

- Brand: Wago

- Product Code: 770-895/080-000

Notes

Variants: | Other pole markings Other versions (or variants) can be requested from WAGO Sales or configured at https://configurator.wago.com/. |

Electrical data

Note on contact resistance | approx. 1 mΩ of contact resistance

|

Connection data

Total number of potentials | 5 |

Number of levels | 1 |

Physical data

Pin spacing | 10 mm / 0.394 inches |

Width | 47 mm / 1.85 inches |

Height | 29.5 mm / 1.161 inches |

Height from the surface | 26 mm / 1.024 inches |

Depth | 14.6 mm / 0.575 inches |

Solder pin length | 3.5 |

Solder pin dimensions | 1 x 0.8 mm |

Drilled hole diameter with tolerance | 1.5 (-0.1 … +0.1) mm |

Mechanical data

Technology | SMI |

Application | Control technology |

Coding | B |

Variable coding | Yes |

Marking | I+ I- L ⏚ N |

Potential Marking | I+ I- L ⏚ N |

Mating force of a plug-in connection | approx. 20 … 70 N (depending on pole number) |

Retention force of a plug-in connection | Locked: > 80 N |

Unmating force of a plug-in connection | Unlocked: approx. 20 … 70 N (depending on pole number) |

Number of mating cycles | 200, without resistive load |

Design | straight |

Plug-in connection

Contact type (pluggable connector) | Male connector/plug |

Connector (connection type) | for PCB |

Mismating protection | Yes |

Note on mismating protection | All WINSTA® components are 100% protected against mismating when: |

Mating direction to the PCB | 90 |

Locking lever | yes |

Locking of plug-in connection | locking lever |

Note on locking system | All connectors for mounted installations (snap-in versions for lighting fixtures or devices, all types of PCB and distribution connectors) are factory-equipped with locking levers to ensure plugs and sockets are securely locked. Additional locking levers are only required for flying leads (plug/socket). |

PCB contact

PCB Contact | THT |

Solder pin arrangement | 2 in-line solder pins/pole |

Number of solder pins per potential | 2 |

Material data

Note (material data) | |

Color | pink |

Insulation material | Polyamide (PA66) |

Clamping spring material | Chrome-nickel spring steel (CrNi) |

Contact material | Copper or copper alloy; surface-treated |

Fire load | 0.231 |

Weight | 10.8 |

Environmental requirements

Processing temperature | -5 … +40 °C |

Continuous operating temperature | -35 … +85 °C |

Note on continuous operating temperature | Insulating parts for temperatures ≤ 105 °C |

Other

Technology | SMI |